Mechanical design plays a pivotal role in bringing ideas to life in the world of engineering and technology. Whether it’s a complex machine or a simple consumer product, mechanical design ensures that these devices function effectively, are durable, and meet safety and usability standards. In this blog, we will explore the fundamentals of mechanical design, its importance, and how it interacts with other design disciplines, including how an electronic design company contributes to the development of high-tech products.

What is Mechanical Design?

Mechanical design refers to the process of planning, creating, and optimizing mechanical systems and components. This includes everything from the layout and structure of a product to its materials, functions, and operational mechanisms. Mechanical design focuses on ensuring that the product performs efficiently, can withstand real-world conditions, and meets any necessary regulatory standards. It involves the application of principles from physics, material science, and engineering to create solutions that address specific needs, whether for industrial machinery, automotive systems, or consumer electronics.

The Core Elements of Mechanical Design

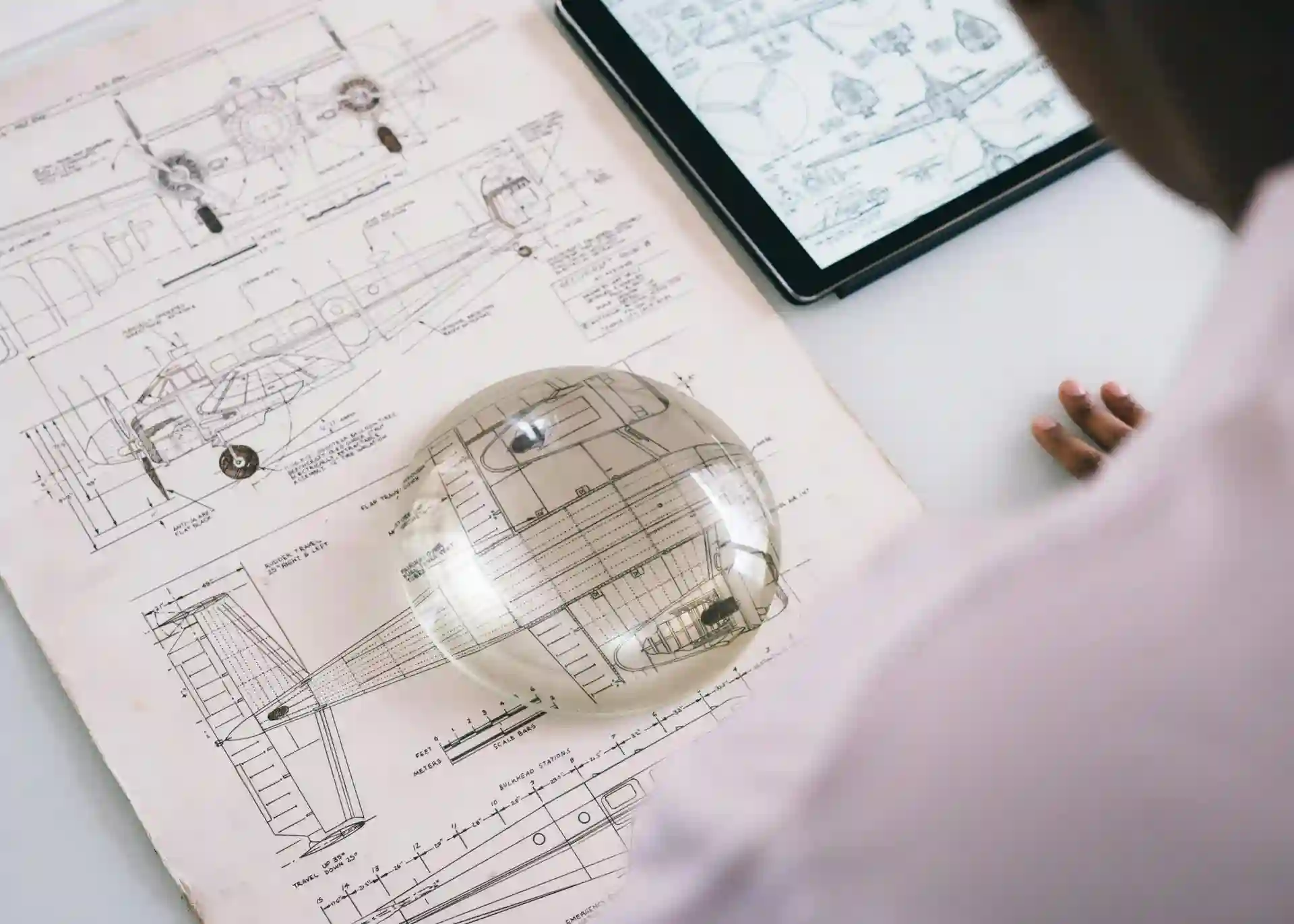

Conceptualization and Ideation: The mechanical design process begins with understanding the requirements of the project and conceptualizing potential solutions. Engineers and designers work closely with stakeholders to define the functional goals and constraints, considering factors such as product use, environmental conditions, and budget. From there, design concepts are sketched out, and potential materials are chosen to ensure the design is both feasible and functional.

Detailed Design and Prototyping: Once an idea has been conceptualized, engineers move on to the detailed design phase. This involves creating 2D and 3D CAD (Computer-Aided Design) models that specify every component’s size, shape, and material. The prototype is then built to test the design’s functionality, ergonomics, and performance. Prototyping is a crucial step that allows designers to test the product in real-world conditions and make necessary adjustments before mass production begins.

Testing and Iteration: Mechanical design is rarely a one-and-done process. Even after prototyping, the design undergoes rigorous testing and refinement. Engineers look for areas where the product may fail or could be improved—whether that’s strength, durability, or user comfort. Feedback from testing ensures that the final product is as efficient and reliable as possible.

The Importance of Collaboration in Mechanical Design

Cross-Disciplinary Collaboration: While mechanical design may seem like a standalone process, it often requires collaboration with other fields of engineering to ensure the product meets all necessary standards. A key player in modern product development is an electronic design company. These companies are responsible for designing the electronic systems that power devices, ranging from simple circuits to complex processors. Effective collaboration between mechanical engineers and electronics designers is essential for creating products that are not only mechanically sound but also technologically advanced.

For example, in consumer electronics, a mechanical designer might be responsible for the housing, buttons, and layout of the device, while the electronic design company would create the circuits and chips that make it function. The collaboration ensures that the mechanical components can support the electronic systems and vice versa. Without this teamwork, devices would fail to deliver the expected performance or usability.

Shared Goals and Vision: The mechanical design and electronic design teams must work toward a common vision. They must ensure that the physical design accommodates the technology and that the technology works within the constraints set by the mechanical components. Through open communication and iterative feedback, both teams ensure the final product meets performance, durability, and usability goals.

How Mechanical Design Impacts Product Performance

Efficiency and Functionality: A well-executed mechanical design can significantly improve a product’s efficiency. By optimizing the physical aspects of the product—such as minimizing weight, reducing friction, or enhancing aerodynamics—engineers can create more efficient devices that perform better. For instance, in the automotive industry, mechanical design plays a key role in fuel efficiency by optimizing engine components and reducing the vehicle’s overall weight.

Safety and Durability: Mechanical design also has a direct impact on the safety and longevity of a product. Engineers use their expertise to select the right materials, design for shock absorption, and ensure that products can withstand wear and tear over time. This is particularly important in industries like aerospace, medical devices, and automotive design, where product failures can have severe consequences.

Cost Reduction: Efficient mechanical design can also reduce production costs by minimizing the number of components and simplifying the assembly process. For example, if a design can be simplified, fewer parts are needed, reducing material and labor costs. This approach to design optimization makes the product more affordable for both manufacturers and consumers.

The Role of Mechanical Design in Various Industries

Mechanical design is integral to various industries, each with its unique requirements and challenges. Let’s explore some industries where mechanical design plays a central role:

Consumer Electronics: In the consumer electronics industry, mechanical design ensures that devices like smartphones, laptops, and wearables are compact, durable, and aesthetically pleasing. The design must accommodate electronic systems and ensure user comfort and usability, which is where the collaboration with an electronic design company becomes vital. The mechanical design supports the functionality of electronic components like batteries, displays, and circuit boards, ensuring that the device is both attractive and functional.

Automotive and Aerospace: In these industries, mechanical design is crucial for ensuring that vehicles and aircraft are safe, efficient, and reliable. Automotive mechanical engineers work on everything from engines and transmissions to chassis and suspension systems. Aerospace engineers design everything from airframes to engine components, ensuring safety, aerodynamics, and fuel efficiency. In both fields, mechanical engineers work closely with electronic designers to incorporate systems like navigation, sensors, and autonomous driving features.

Medical Devices: Mechanical design in the medical device industry involves creating products that are not only functional but also safe and comfortable for patients. Devices like MRI machines, pacemakers, and surgical tools require precise design to meet both medical standards and ergonomic needs. Mechanical design ensures that these products are reliable and durable, while the integration of electronics is handled by the electronic design company.

Industrial Machinery: Mechanical design is essential for developing machinery used in manufacturing, construction, and energy sectors. Engineers must design robust, efficient, and durable equipment that can withstand heavy use and adverse conditions. The design of gears, motors, and hydraulic systems is fundamental to the performance of these machines.

The Future of Mechanical Design

As technology continues to advance, mechanical design is becoming more sophisticated. With the rise of automation, AI, and 3D printing, mechanical engineers are now able to create more complex and innovative products at a faster pace. The future of mechanical design will likely involve greater collaboration between various fields, with designers from mechanical, electronic, and software engineering working even closer together to create seamless, integrated solutions.

Sustainability is another key trend driving the future of mechanical design. As environmental concerns grow, engineers are increasingly focused on designing products that use fewer resources, are more energy-efficient, and are easier to recycle. This emphasis on green design practices is pushing the boundaries of mechanical design and ensuring that future products are both innovative and environmentally friendly.

Conclusion

Mechanical design is a critical component of product development that ensures devices are functional, safe, efficient, and reliable. By combining engineering principles with creativity, mechanical designers shape the products we use every day, from consumer electronics to industrial machinery. The collaboration between mechanical designers and an electronic design company ensures that products can not only perform mechanically but also integrate seamlessly with advanced technologies. As industries continue to innovate, the role of mechanical design will remain central in driving technological advancements and creating the products of tomorrow.